How do you decarbonise a dehumidifier?

Ship's Conservation Engineer Nicola explains our journey so far to decarbonise the SS Great Britain and explore what we can do for the future.

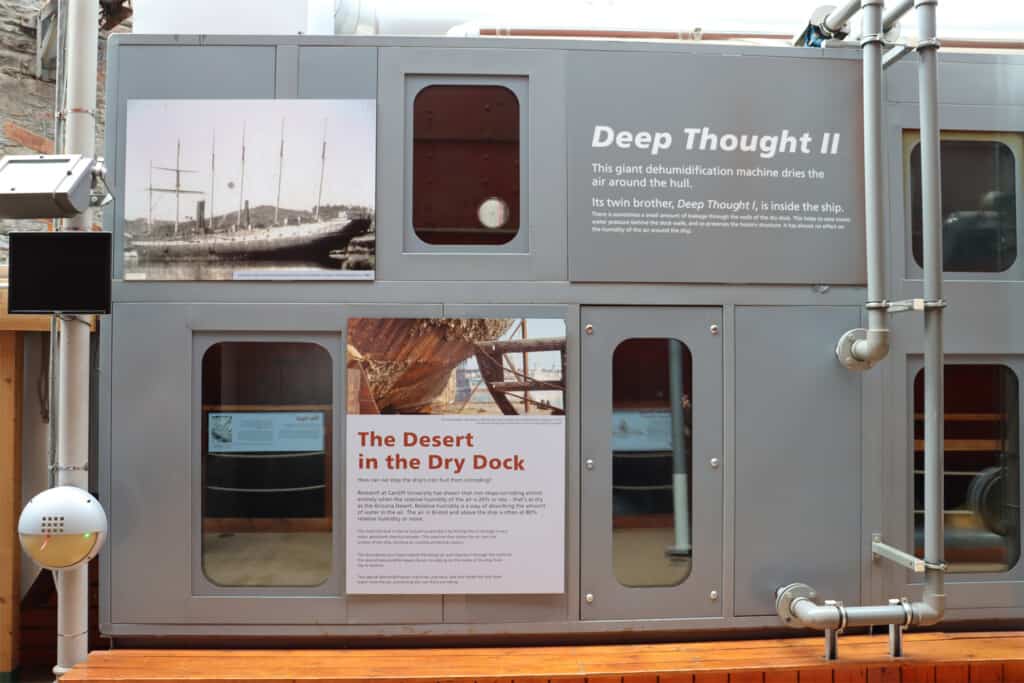

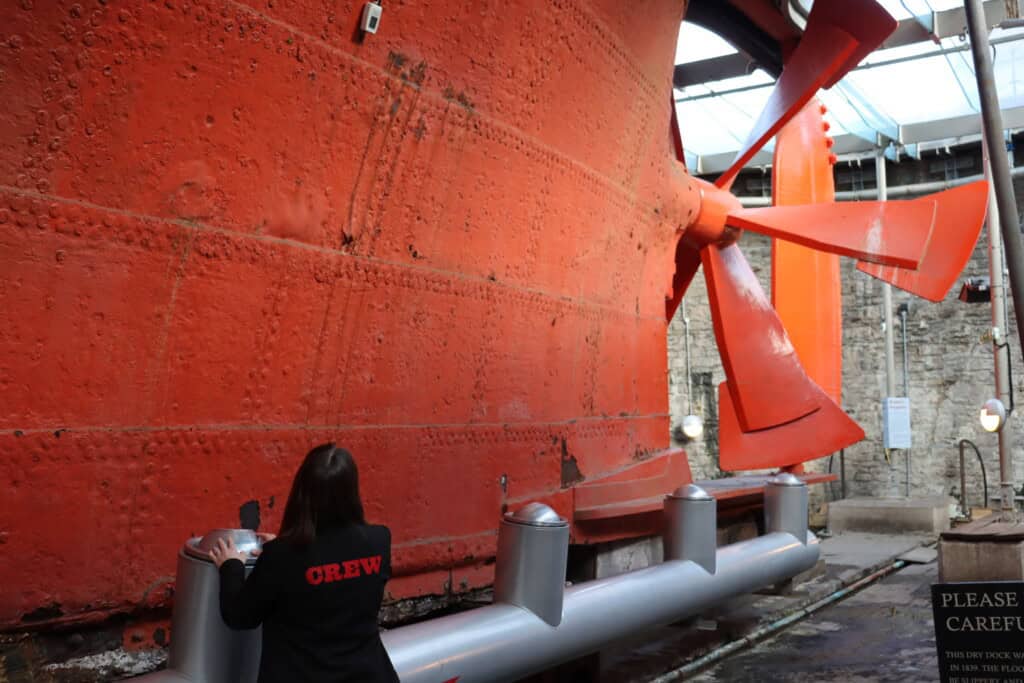

We conserve the SS Great Britain in its original Victorian dry dock by keeping the air around the ship very dry. This stops the iron from rusting and protects the ship’s structure. To do this, we have two custom-built dehumidifiers that use heat from gas and a material called a desiccant to dry the air. We are working on ways to reduce the CO2 emissions of this process and make it more sustainable.

Our latest project builds on our previous award-winning work to better understand the way our drying system works and add energy-saving technology, which has already reduced our energy use by about 25%. We are now exploring whether the gas-powered drying system in our dehumidifiers can be replaced with a lower-carbon option.

At the time the dehumidifiers were designed, a big share of the UK’s electricity came from coal power stations. Installing gas burners directly in our dehumidifiers was a more environmentally friendly way to solve our unique conservation challenge than a system using lots of electricity generated from coal. However, in recent years coal power stations have shut down and been replaced by greener renewable energy, like solar and wind. This change means electricity is more environmentally friendly and has now overtaken gas as the greener option.

This isn’t quite as simple as it sounds, because electricity is very expensive compared to gas. If we did a simple swap of gas for electric heating in the dehumidifiers, we wouldn’t be able to afford enough electricity to create the dry conditions we need to stop the ship from rusting.

A possible way to solve this problem is with a heat pump. Instead of generating heat, a heat pump can move heat from a cooler area, making it even colder, to a warm area making it even warmer. This works in the same way as a fridge, which makes the air inside colder by heating up the air outside. A heat pump could take heat from the ship, dry dock and even outside, and use it to create the hot conditions needed for our desiccant to operate. Better still, a heat pump can move up to 4 or 5 times as much heat as the electricity needed to power it, making it much cheaper and more energy-efficient than an electric heater.

Changing the design of our custom drying system to use a heat pump is a big challenge, since the ship and dry dock have very limited space available for big equipment. So, to make this change possible, we need to do two things:

- Make all other parts of the system as efficient as possible, so we can use the smallest possible heat pump.

- Devise a way to fit the new equipment into the limited space available in the ship and dry dock, while re-using as much of our other existing equipment as possible.

The project we’re working on now is exploring ways to achieve this. Thanks to expert advice funded by the Bristol City Leap Community Energy Fund, we have created a computer model of the dry dock dehumidifier. This technique uses data collected in the dehumidifier to calculate how energy and moisture move through the space. The results from this work have helped us plan our next steps:

- Upgrade the sensors inside the dehumidifier. Our work so far has included upgrading the sensors around the ship and dry dock, giving new information about the flow of dried air and contributing towards the 25% energy savings we have already achieved. We are now looking more closely at the sensors inside the dehumidifiers. The computer model revealed that some of these sensors are not in the best locations to measure important parts of the air flow correctly. We will move these sensors, and install some new ones, to give us better data for future calculations.

- Experiment with different temperature settings. It will be easier to make the new equipment smaller if we can run the drying part of the dehumidifier at a lower temperature. Our previous work has lowered the temperatures a little bit, the next step is to experiment with other settings like air flow rates, to see if these temperatures can be reduced even more.

- Keep the dry dock walls and floors as dry as possible. The historic dry dock is a listed structure and it’s not possible to completely stop water from the harbour leaking into the dock. But by using pumps, pipes and gutters we can control where the water goes and stop it from making puddles near the ship. Less water near the ship means less work for the dehumidifier to keep the iron dry.

- Fine-tune the air flows around the dry dock. Air from the dehumidifier needs to reach all parts of the ship’s hull to stop rust. We aim for an average of 20% relative humidity, but our new ship and dry dock sensors show that the humidity can range from 15-25% in different parts of the ship. We are aiming to make this more even by adjusting the amount of air flowing in each direction as it leaves the dehumidifier.

Once we have completed these steps, we can move on to the next stage of the project, to design a system which keeps the ship safe in a more environmentally friendly way.

We are grateful to Bristol City Leap Community Energy Fund, Julie’s Bicycle, the University of Bristol, and Ray Daniels for supporting this important work.